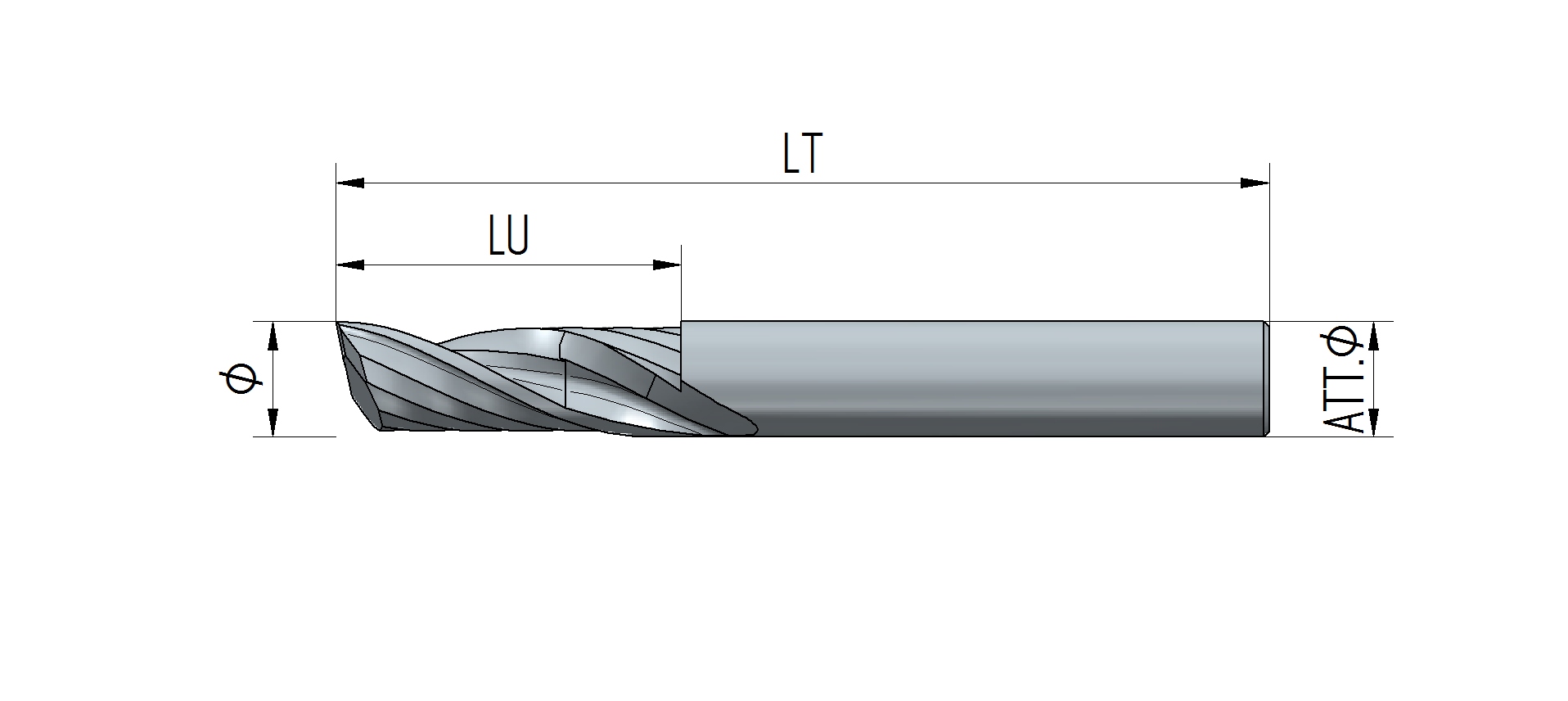

Carbide end mills (Z=1) with coating for processing aluminium – Short series

The single-edged aluminum end mills (Z=1) made from carbide (HM) and featuring a special DLC (Diamond-Like Carbon) coating are designed for high-performance machining on CNC machining centers.

These end mills are ideal for processing aluminum even without lubrication, making them a versatile choice for dry machining. The innovative cutting geometry combined with the lapping finish on the cutting edges ensures optimal chip expulsion and enables burr-free processing, even on painted materials.

Perfect for a range of operations including drilling, milling, grooving, and hinge-cutting, these tools are essential for machining aluminum bars, furnishing accessories, and doors and windows without the need for lubrication.